|

» Deutsche

Fassung: hier klicken! |

LRP Shark 18 Monster

Review, Part

1

|

|

|

Small-sized

offroad(-cult) |

|

|

|

"Micro racing is fun!"

"Truggy-driving is cool!"

"Monster Trucks are the greatest!"

These are the three biggest trends that you

could experience as an R/C car driver in the last five years. All of

them brought loads of more or less sophisticated models to fill the

new classes and add some colour to the R/C car world.

LRP-Electronic

seems to aim at combining all those trends into one single car. How?

By building a small 1/18th scale truggy

and naming it "Monster"!

LRP offers their Shark 18 Monster in two versions: You have the

choice between the completely assembled (ARTR-) Truggy without any

rc-gear for about 149,90 Euros or you could go for the full

RTR-Package that includes anything you'd need as a hobby starter for

229,90 Euros.

For the this review

WR-RC-Racing

hooked me up with the RTR-version of the LRP Shark 18 "Monster"

The following remarks therefore refer to the test sample and

especially the measured values cannot be unrestrainedly generalized

due to serial dispersion.

Although "RTR" might sound like "unwrap and go"

such models should always be disassembled and checked. This can be

easily done thanks to the well illustrated manual which is also a

good reference for future maintenance work.

TECHNICAL

DATA

Length:

263mm

Wheelbase: 168mm

Width: 196mm

Height: 92mm

Weight: 730g

SUPPLEMENTARY

EQUIPMENT

27MHz

transmitter

servo, receiver

380-size motor, ESC

batteries for vehicle and transmitter, charger |

|

All external hyperlinks marked

like this will be opened

in a new browser window!

|

|

|

Shark

18 Monster: The package |

|

|

|

As expected, LRP will

not let down their customers when it comes to funky package design.

The compact box features a ‚see-thru’ window while the coloured

cardboard is used to promote some spare- and hop-up parts. A small

photo gallery affirms to a still undetermined consumer that this

product has been developed and tested by some of the swell in the

(international) R/C car scene – well, then!

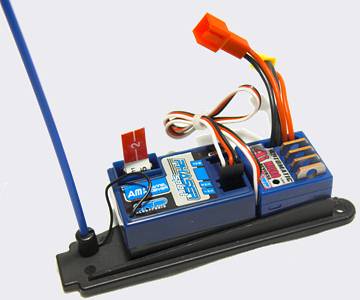

What has always counted more for us are the ‚inner values’. The RTR

kit is (nearly) absolutely complete: The Shark 18 has been equipped

with a Phaser 27 MHz (AM) receiver and an A.I. micro ESC – meaning

no cheap ‘RTR-edition’ components but regular, off-the-shelf LRP

products.

The transmitter is all standard: charging jack, trim and servo end

point adjustment for the steering are included and should be enough

for a start.

The additional equipment consists of a 600mAh battery to power the

Shark 18 Monster, a wall socket charger and eight (non-rechargeable) AA

cells for the transmitter.

While shopping, all newcomers should equip themselves with a set of

rechargeable transmitter batteries plus charger.

|

|

|

Shark

18 Monster in details |

|

|

|

"solid"... "overcrowded" ... "cute!"

Guess those were my first thoughts when I had delivered the little

truggy from its bodyshell.

Luckily, the crowded look only comes from the standard components

that the Shark 18 Monster is fitted with. Using mini-components (micro

servo, small FM-receiver from a slow-flyer) the chassis would

certainly look more orderly, but parts in standard size are quite

tough and budget-priced.

The chassis actually debuted with the Shark 18 buggy – which LRP

promoted as a scaled-down 1/8th buggy. Just as well, because the

dimensions of the chassis remind more of a gas powered vehicle than

of a frail electric car. The construction itself is a clever mix of

both types with some intriguing details. The chassis hasn’t been

changed for the Monster model, but the suspension has been made wider,

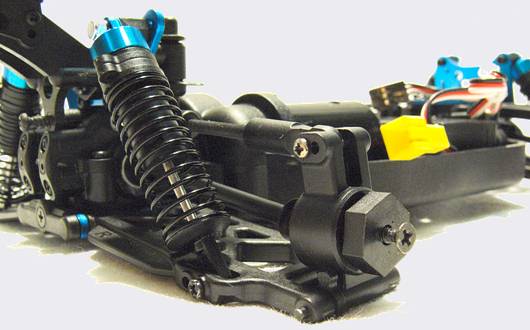

featuring a PBS-suspension at the front.

|

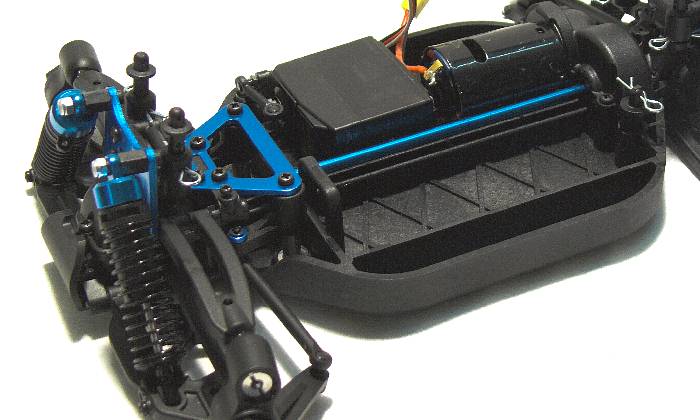

The electronics can be (apart from the

taped-in servo) quickly removed from the chassis because they are

mounted onto the battery strap. Down below you can see much more of

the chassis. It's of a ‘tub-type’ with lots of things moulded to it,

hence the Shark 18 Monster consists of a surprisingly small number of

parts.

The chassis comes with the lower halves of the gearboxes, all

supports for the drive train and the inner hinge pin mounts.

If it weren’t only twenty centimetres long you could think of a

1/10th scale chassis because the thickness of 2.5 millimetres seems

quite beefy with the small scale. The plastic is reassuringly stiff

and light – it seems to be fibre-glass reinforced nylon. All

stressed parts are secured with 2.6 millimetre tapping screws.

|

|

|

|

|

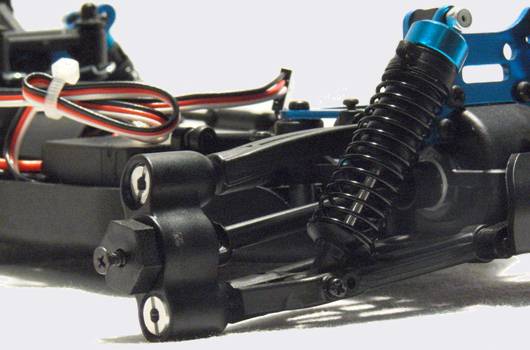

The

design of the front suspension is very close to the

1/8th scale buggy concept. Due to the pivot ball

suspension the upper arm has to support the steering arm

and can therefore not use a tie rod. The whole steering

construction reminds of the bigger-scale ancestors as

well. The double linkage of the steering itself is more

of the 1/10th standard again, while the servo –deprived

of its mounting lugs- is held in place only by a patch

of double-sided adhesive tape. |

|

The cast-aluminum motor

mount is a firm base for the 380-size motor and also

quickly dismantled by loosening two screws. The

construction of the Shark 18 would make it quite tricky

to adjust the meshing between pinion and main gear,

hence blue anodized adaptor plates with fixed mounting

holes are used. This way, five different pinion gears

can be used. (11, 13, 16, 19 and 21 teeth)

A precisely fitting gear cover protects everything from

dust and also stiffens this critical part of the chassis

at the same time. |

|

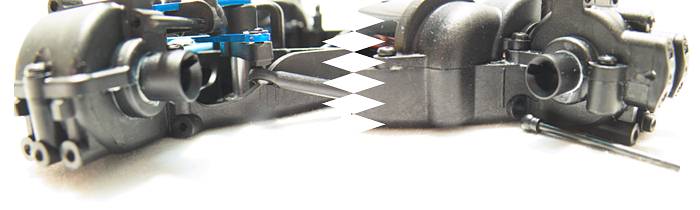

Why be

complicated when there’s an easy way? Instead of

attaching frail hinge pin holders, LRPs’ Shark 18

Monster

uses all of the tub chassis and integrates the hinge pin

mounts into it. The rear end uses a ball-type design

which makes everything more crash-proof and allows the

use of different toe-in blocks. |

|

|

|

|

Suspension |

|

|

The Shark 18 Monster comes with a

PBS-system at the front and conventional hub design at the rear

suspension. Four oil filled shocks provide remarkable 3 centimetres

of travel (depending on the position of the shock on the lower arm

and the shock tower)

|

|

PBS-systems are a little trickier to

set up due to their construction but LRP found a clever solution to

compensate this: The arms got a little ‘peephole’ – when the thread

of the pivot ball is half way in, the setup is OK. Fly, huh?

PBS-systems are a bit more

sensitive to crashes because of the bigger leverage forces (like on

the pivot ball thread which is screwed into the suspension arm)

Hence these suspensions are normally built more ruggedly than

conventional c-hub systems. The Shark 18 Monster is no exception here:

Its steering arms could compete with a Team Losi XXX-4 (1:10) buggy.

|

|

What is a pivot ball suspension?

At the front the

suspension has to allow movements in two ways: up and

down for the shocks, left and right for the steering.

With conventional c-hub systems these two directions of

movement are performed by two separate parts: The c-hub

allows vertical movement and inside of it you find the

steering arm which can move horizontally.

The pivot ball suspension uses one single

suspension part that is able to move in both axes which

is realised by using, well, balls

The steering arm

contains two massive ball supports which can be set up

without any play by the help of aluminum inserts.

Depending on how far the steel balls are screwed into

the suspension arms you can adjust the caster – and with

a three-ball PBS even the toe-in at the rear suspension.

More on this in the

R/C-clopedia! |

|

|

The suspension arms are made of a more flexible material but this

shouldn’t have any negative effects on the whole construction. In

order not to overstress the shocks, the arms have lugs on the

underside to limit the maximum suspension travel. |

|

Now that we’re talking about shocks: Luckily LRP equipped the Shark

18 Monster with full-fledged oil filled shock absorbers. Alas, they

cannot keep up with the excellent quality of the chassis as they are

sloppily filled.

But filled correctly (the diaphragm could be a bit bigger too!)

they’re really smooth and soft. Unfortunately the manual doesn’t

tell about the actual oil that the shocks have been filled with but

20WT/200cps should be just about right.

Also the spring preload needs a bit of help: one clip at each front

shock and two at the rear will make the suspension arms stay level

to the ground and provide for remarkable 15 millimetres of ground

clearance.

As you can see on the pictures on the right the whole suspension can

do without e-clips: the hinge pins are kept from falling out by the

front bumper or the rear plate respectively. The rear-hub pins are

held by a (really firm) press fit.

|

|

|

You can

be quite inventive when setting up the Shark 18 Monster:

The shocks have two positions on each suspension arm and three at

the shock tower in order to master any surface that you can think

of. The caster of both front and rear suspension can be adjusted

while the toe-in remains fixed.

|

|

|

A

Centershaft, two diffs, four universals and a few ball bearings |

|

|

|

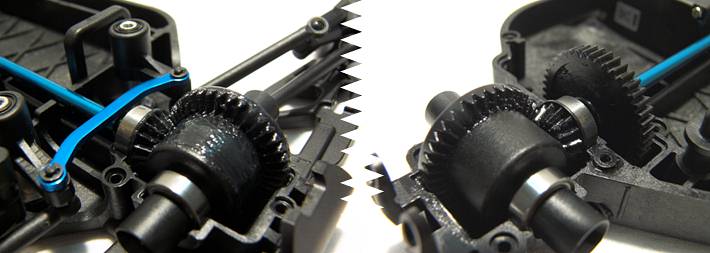

Unlike in bigger scale 1/10ths’ or even 1/8ths’ everything could be

quite simplyfied for this mini-truggy: Thanks to the stiff chassis

there was no need to separate the bevel gears from the main shaft

but simply stick them onto the 5-millimetre aluminium shaft. The

bearing of the central shaft is realised by the bevel gears and the

spur gear so that there remains a bit of flexibility from the

plastic chassis.

|

|

|

|

Simple and rugged: Thanks to a lot of plug-connections

(also at the diff-outdrives) the whole driveline is

quickly dismantled. The diff outdrives are made of

plastic as well, but thanks to their closed design they

do not need any outdrive-saver rings.

|

|

|

The bevel gears run smoothly out of the box and without

being notchy. Gears and diff innards are packed tightly

with sticky grease (which has been removed for the

photos, as far as possible)

|

|

|

|

Contrary to the good impression that the Shark 18

Monster

has made so far, you have to ask yourself what LRP might

have had in mind while designing their universal shafts:

Compared to the four-millimetre aluminum main shaft

these three millimetre plastic shafts (which have to

transfer three to four times the torque) look rather

‘provocative’ - to put it in a nice way.

The only metal part in the shaft is the drive pin; even

the cardan joint is made of plastic and engages with a

nearly one-millimetre lug. There would be enough space

to make the prop shafts 50 percent bigger.

"And that works?" – more of a rhetorical question, but

we will see!

I definitely like the idea that LRP decided to use the

widespread 12-millimetre wheel hex for the Shark 18. So

it is no problem to use 1/10th sedan tires when the

track allows it. However you will need a screw with a

bigger head or a small shim to attach it securely.

|

|

|

|

Checkpoint! |

|

|

|

LRP's Shark 18 Monster – a

1/18th scale truggy with lots of clever details, supreme quality in

assembly plus material and ...

… universal shafts that don’t want to have anything to do with the

rest of the car; or at least make you want to believe that..

The whole truggy is purpose-built: as simple as possible without

compromising stability or suspension geometry. So it doesn’t come as

a surprise that the Shark 18 can be almost completely disassembled

in about ten minutes.

The quality of the RTR assembly is excellent for the most part:

Every screw is tight, the suspension is set up and also the wiring

leaves nothing to be desired.

The sloppily filled shocks are a nuisance and with the wing stay I

had to find a damaged thread – annoyingly, in the chassis.

Text and pictures by

Aaron Banovics

Translation by Markus

Simon

This review has been published on

www.offroad-cult.org

on 02-10-2007.

|

|

|