|

|

Piranha P2

Do-it-Yourself Buggy

|

|

|

|

|

Lean

mean killing machine ... |

|

|

|

Looking at the variety of currently

avaliable 2wd EP buggies ranging from low price rookie model up to

high end team kit you'd nearly have to justify yourself for bringing

up your own thing. Alas, lots of interesting cars will only be

offered as RTR-packages but still you can find hobbyists out there

who enjoy building their whips clearly as much as racing them.

Markus Simon ("madmax" in the

Forum) proves to be one of those modelers. His "Piranha"

buggy does it again, the "P2" alluding to the second edition. Let's

see if it can keep up with its namesake!

All hyperlinks marked like this

will be opened in a new browser window!

|

|

|

Rounding up |

|

|

|

The Piranha buggy concept is meant to combine ideas and technologies

currently used in all different sections of R/C car racing.

-

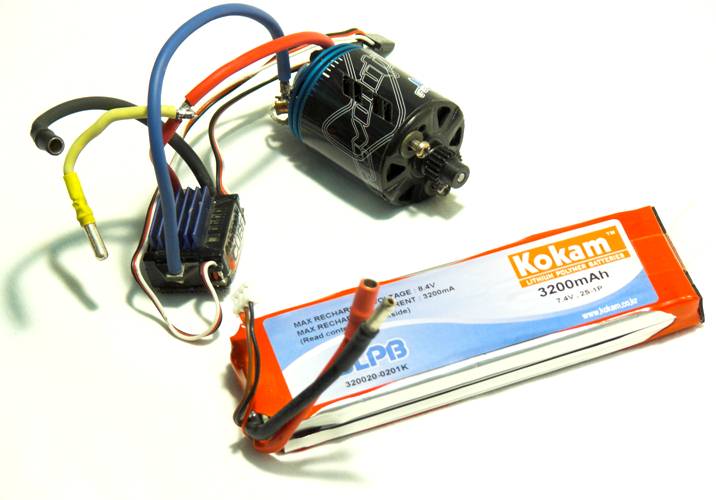

Lithium-polymer batteries:

The newest generation excels the proven nickel

metal hydride batteries in power density at a much

lower weight. A Li-Po pack with only marginal voltage

drop under load condititon and a capacity of 3200 mAh weighs just about 200

grams and is lots smaller than an equivalent

pack of older generation cells.

The Piranha P2 employs two Kokam 3200HD cells

providing 7.4 volts when connected in series.

Most lithium-polymer batteries are only covered in a

thin kind of foil which makes them light but also

vulnerable to mechanical damage. So in the Piranha

P2 part of the chassis' job is to protect the

batteries effectively.

Lithium polymer cells need chargers that are

suitable for this kind of battery type. Like their

nickel buddies they're not too keen on overcharging

hence lipos mustn't be connected to any conventional

nicad/NIMH charger! (also see

battery-FAQ

concerning this!)

-

„Mid motor“:

Any usual 2WD buggy will have its motor located

behind the rear suspension. This moves the center of

gravity backwards and thus helps the rear end to

gain more traction. The downside of having the motor

mass out of the center is a certain amount of

instability: When cornering, the car will

-overstatedly- act like a pendulum.

With the battery of the Piranha P2 only weighing

half of any conventional nicad/NIMH pack the COG

issue is solved, so there are no objections

against moving the motor to the inside of the car -

except one's really into making wheelies.. Hence the

mid motor concept.

-

„Push-rod“-linkage:

Horizontal shock absorbers became famous with the Tenth-Technology „Predator“

buggy.

Inherent hassle with track setup and complex linkage

geometry kept them from being more commonly used.

On the other hand low profile shocks would

definitely assist a cuneiform 2WD buggy outline with

an emphasis on rear end grip. In times when

additional front end grip is needed another wing in

the nose area can be attached effortlessly - so

let's have a go!

|

|

Robitronics' ICube ESC is one of the first lipo-compatible speed controllers for brushed motors. It will

supply the Peak Racing Vantage motor with the energy

provided by 2s Kokam cells. |

Looking at this setup, it doesnt't take a genius to figure out that

the Piranha P2 will never be race-legal; but nevertheless: This is

about the joy of building plus testing and about innovations!

But there remains a question that might irritate some readers ready

to experiment: How on earth should complex parts like suspension arms,

hub carriers or even gear parts be produced? Not at all, for the best of it

- because building those spare parts would cost way too much money

and time!

The thoughtful hobbyist is likely to start out with a complete donor car

and therefore prevent himself from facing total darkness when it

comes to more delicate details like suspension geometry. A

Team Losi

XXX Kinwald Edition had been the favourized candidate for

the Piranha P2. As the P2 would somehow use both front and rear

suspension

all the holes have to be copied to the new chassis accordingly. To

accomodate the mid motor setup while efficiently protecting the lipo

pack at the same time a tub chassis has to be built.

|

Laminating 101

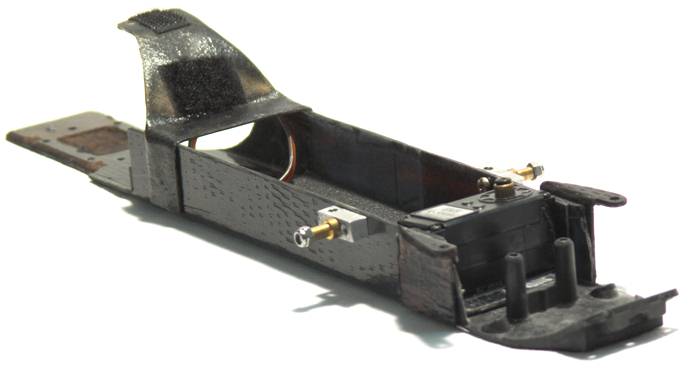

The chassis of the Piranha consists of a hand laminated

u-profile which is cut and drilled after moulding. In

order to save expenses and to facilitate machining it is

designed as a sandwich construction. This means that

only the first and last layer will be carbon fibre and

provide most of the laminates' stability.

In between glass fibre cloth is used as an easy to

handle and light weight coupling layer. The core is made

of Kevlar 49 high module fibres being an optimum

material due to their low specific weight and even more

so enhancing the chassis' impact strenght.

A planed block of wood is used as a positive mould -

either end being about five centimetres longer than the

reinforcement layers of the chassis. The radii of the

longitudinal edges have to be adequately shaped to avoid

residual stress. Furthermore the mould has to be higher

than the actual chassis because cut-off has to be kept

in mind. The inner width has to be in accordance with

the lipo pack that will be used. |

|

To avoid the complicated treatment of the wooden block

with mould release agent it has to be completely wrapped

in PET foil. Upon this the epoxy impregnated layers of

reinforcement fibre have to be arranged.

When the chassis reaches a thickness of about 3-4

millimetres it is covered in another piece of foil. Now

the excess resin has to be removed from the laminate. In

order to do this it has to be pressed between panels,

held together by c-clamps. (First from the top, then

from the sides) To ensure a constant laminate thickness

the panels have to be shimmed with small aluminum plates

- 3mm for the bottom of the chassis, 2mm for the sides.

Laminating uses hazardous materials, machining will

produce particulate matter that may be harmful to your

health - hence it is advisable to wear proper protection

masks and gloves!

|

|

|

|

|

|

It's taking shape ... |

|

|

|

Some work has

still to be done on the Losi-compatible profile before it starts

resembling a buggy. The chassis has to be stiffened towards the

gearbox at the rear and the bulkhead at the front. Due to their

complex shape these reinforcement parts are modeled out of cardboard

and then adapted to the chassis.

All drilling has to be done with similarly high precision,

especially when it comes to the mounting holes of

suspension-relevant parts like the rear pivot block.

At the front end the kickplate of the XXX is ground down to fit the

slimmer chassis. Instead of attaching it with four counter-sunk

screws it is roughened up and extensively glued into place with

epoxy. This kind of assembly is likely to take much more abuse than

a bolted connexion due to the better transmission of force. (Given

that it has been done with care)

The steering servo needs gluing too: It's the only way to fix a 22mm

high "low profile"-servo after it has been deprived of its mounting

links. At least it is glued in a forward-thinking fashion so that it

can still be opened to replace gears or bearings when required.

At the rear end it goes on with the gearbox. It is simply turned

around together with the shock tower and mounted onto the chassis.

That's why the rotating direction of the motor has to be reversed.

This means not only a simple change of the motor wires but also

adjusting the timing respectively. Turning the endbell 180 degrees

would have the same effect but you'd lose the timing marks for

orientation.

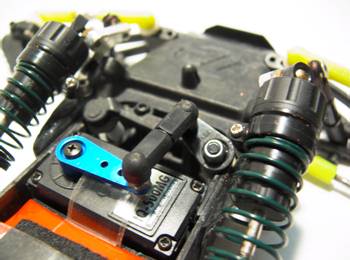

Back at the front end the Piranha P2 already starts taking the shape

of a buggy. Corresponding holes have to be drilled into the chassis

to mount the shock absorbers. The rocker pins are bolted into the

Losi bulkhead. The bell-crank levers are ball raced to provide a

smoothly working suspension. Additional rubber pads prevent the pins

from breaking in rough conditions. Some plastic rod ends, threaded

bolts and Tamiyas' "mini CVA shock unit II" get the front suspension

up and running. Front buggy springs from Team Associated are used to

find a reasonable setup. The rear end suspension uses conventional 1

inch Losi shocks. Two things have to be paid attention to: The

center of gravity is a little bit more towards the front, so a

softer rear end will be needed. Then again an overall softer setup

is required due to the considerably lower vehicular weight of 1200

grams.

|

|

|

Access

all areas: a closer look |

|

|

|

Transmission

powered by Team Losi:

All the gears are taken fom the first XXX-series

providing an internal gear ratio of 2.56:1. The ball

differential has been equipped with a ceramic thrust

bearing from Corally because the thin thrust washers of

the original diff are likely to run in and break apart

when confronted with higher moments of torque.

|

Because the gearbox is

turned to fit into the Piranha P2 the rotating direction

of the motor has to be reversed too. Consequently, only

timeable motors (or brushless motors, which are timed by

the controller) can be utilised in the P2. The preferred

rotating direction has to be set by adjusting the timing. |

Both front and rear end

are taken from the

Team Losi XXX-Kinwald. The front suspension uses thread

end bolts instead of the rather frail hinge pins and

e-clips. Thus play is reduced and the suspension gains

more reliability and overall strenght. Also the rear end

has been deprived of all its e-clips: a set screw in the

rear hub is holding the hinge pin in place.

The rear arms are reversed left to right in order to

draw the rear axle nearer to the motor and therefore

move the centre of gravity a bit backwards. |

|

|

|

No more has the front

shock setup anything in common with the stock Losi XXX.

The push rod suspension features ball raced rubber

padded rockers and Tamiya's "short shock-unit II". The aluminum parts on the main

chassis act both as a shock mount and battery strap

holder at the same time. |

|

|

Due to the mid motor setup and

the slim chassis ridiculously little space is left for

the steering parts. Hence the original servo mounting had to

be left behind.

A 22 millimetres high

"Low-Profile" Servo (GWS IQ 500-MG) is used

instead. Cut down as far as possible it has to be CA'ed

into the chassis. Furthermore, the connection cable to

the receiver was given a new exit on the broadside of

the servo. All the internals can be reached from the top

side - so there is no need to detach the whole thing any

time soon.

The steering mechanism itself is a modified Losi-design

built to collaborate with the new steering servo position. |

|

|

|

|

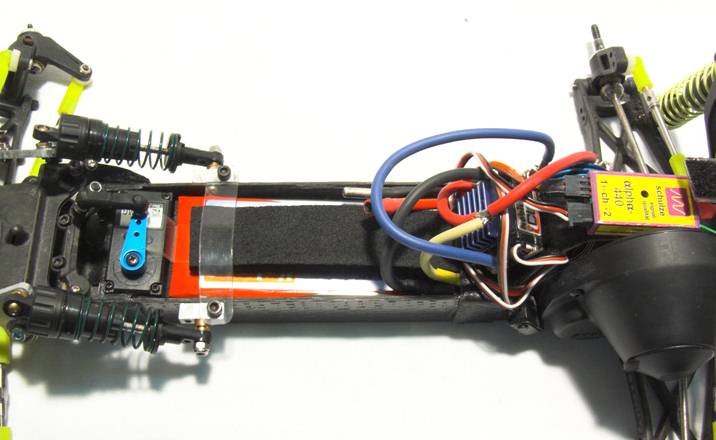

"Economy" is the thought

that comes to mind: space is pretty limited in

the race - ready chassis. All components have to be

crammed together, the ESC even using what little

vertical space is left. But still everything can be

exchanged with no more difficulties than in any other

2WD buggy. |

|

|

|

Cheers!

From bottle to body... |

|

|

|

Empty 2.5 litre PET bottles come in handy whenever you feel the need

for building your own bodies or rear wings. (CocaCola called it the "shape

bottle" for a reason!) Acting like heat shrink

tubing when treated with a hot air gun they wrap tightly around the

Piranha body mould carefully shaped out of balsa wood.

A PET body like that comes out extremely light weight - without

losing any strenght when compared to polycarbonate shells. The body

can be painted with your usual acrylic based polycarbonate paint.

A detailed how-to on moulding your own parts using PET bottles can

be found

here!

|

|

|

Test-Drive! |

|

|

How's it gonna

drive? Was it worth the effort? Please let that chassis hold!

… Thoughts like these cross your mind when the battery is

connected for the first time and the control-LED of the speed

controller lights up. Driving a car that took way more time and

commitment than a kit or even a ready-to-run for the very first

time triggers totally different emotions. Just like launching a

new untested sailplane. Well, the Piranha P2 was spared any

flights at the beginning so the tension loosens as the sleek

buggy rolls off unhurriedly. The P2 cannot be compared with its

aquatic namesakes yet - all the better for trimming the steering.

Some cautious cornering, then comes the straight; the first

opportunity to kick it in the guts: Theoretically, the Piranha

accelerates about 20 per cent faster than its XXX predecessor.

In practice the P2 is simply as swift as an arrow - so fast that

the next corner is taken off-the-road for safety reasons. It soon

becomes clear that the Piranha P2 has a noticeable tendency

towards understeering - given the absolutely stable handling

performance this is an extremely positive sign for a rear wheel

driven mid motor car that woulld be expected to show a greater

oversteering tendency. Understeering can be traced back to the

facts that the front suspension setup is rather hard and the

steering throw was reduced to a mere 70 per cent. Latter had to

be done because the the steering linkage did not have the

optimum lenght. So it's confidence and a good feeling on the way

back to the workbench to prepare the Piranha for the nex test

session. By the way - the reversed motor could do with a little

more timing ... !

There are many ways to R/C

car racing. Being engineer, test pilot and race driver at the same

time is definitely one of the most entertaining ones. It needn't

automatically be a high end racer or even a world championship car -

those models are mostly built by renown manufacturers with years of

racing experience.

But also as a layman one can be proud of one's work - and getting a

whole lot of background information about setup, suspension dynamics

and materials can be listed as positive side effects.

A second hand car is easy to get and helps making your first steps

towards the DIY buggy!

More infos about a new CR-based Piranha at our messageboards! |

|

Text and photography by Aaron Banovics,

translation by Markus Simon

This article has been published on

www.offroad-cult.org

on 05-31-2007.

|

|