|

|

|

»

Deutsche Fassung: hier

klicken! |

Kyosho

Inferno ST US Sports

Part #1:

Overview and Construction

|

|

|

|

|

Once upon

a time ... |

|

|

|

"Inferno-ST"

- with some old stagers this name might ring a bell. Right, Kyosho

offered an "ST" model in the age of the Turbo-Inferno. Based on an

already ten year old buggy chassis, with bigger tires, adjusted gear

reduction and a truck-bodyshell Kyosho's first ST model was

virtually the ancestor of the now popular truggy class.

The truggy of today is designed around a buggy chassis just as well.

It is therefore stretched and equipped with longer suspension arms

and shock absorbers. The bigger tires (about 140 mm in diameter) are

compensated with a bigger spur gear in order no to overexhaust the

engine.

Like that, truggies are nearly all-purpose models: Thanks to the

buggy-like suspension they cut a fine figure on the race track, but

the massive tires together with a vehicle-width of clearly over 400

mm and long suspension travel allow full blown bash heats just as

well.

Whatever use the truggy is put to - the buggy chassis and the

drivetrain normally stick it out unscathedly. 1/8th scale buggies

got their reputation of being the toughest and sturdiest offroaders

for a reason.

So it was just a matter of time until Kyosho would enter the new

scene with a truggy model based on their pretty successful Inferno

MP series. Now there are already three versions to choose from:

For this review

Kyosho-Germany

provided us with the Inferno ST US Sports which will possibly

replace the Sports as a beginner model.

The following remarks therefore refer to the test model and cannot

be unrestrictedly generalized e.g. due to serial dispersion,

especially with the measured values.

Although "RTR"

might sound like "unwrap and go" such models should always be

disassembled and checked. Gas powered models, especially of this

size, can be dangerous when out of control due to a loose bolt. You

also get to know the vehicle along the way - sort of dry practice

for the real thing, in case that maintenance work and repairs have

to be done.

TECHNICAL

DATA

Length:

500mm

Wheelbase: 350mm

Width: 415mm

Heigth: 150mm

Weight: 3450g

(manufacturers' data)

SUPPLEMENTARY

EQUIPMENT

27MHz transmitter,

servos, receiver

4.6ccm engine

fuel bottle

glow plug heater |

|

All hyperlinks marked

like this will be opened

in a new browser window!

|

|

|

A look under the hood

- and a quick overview |

|

|

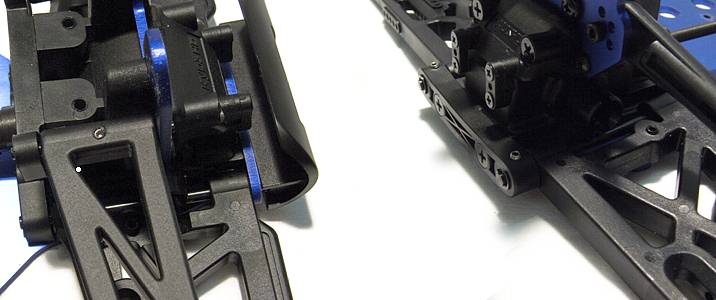

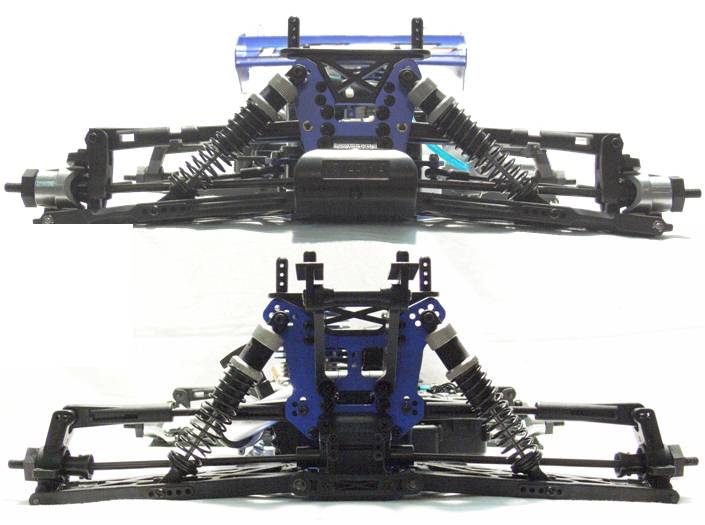

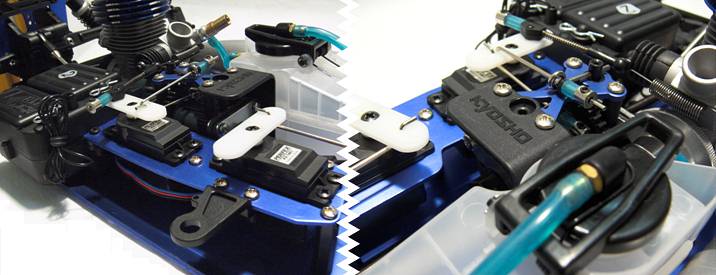

Without tires and body the Inferno

ST could nearly pass for a buggy. On the second glance the longer

suspension arms stand out - and - for the connoisseur of the MP 7.5

buggy chassis - the chassis plate that has been stretched to either

end.

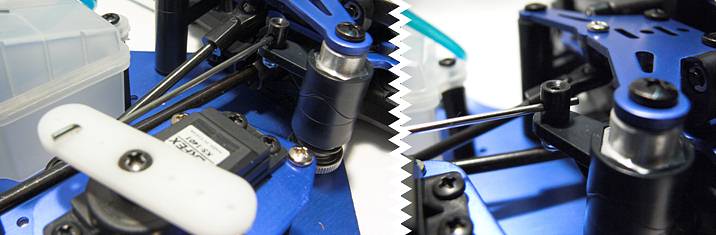

The layout feels pretty clean. At the moment Kyosho is the only

manufacturer that does not take advantage of a laydown steering

servo. By this they fail to take the "important" opportunity to

lower the center of gravity by 0.2 millimetres; instead Kyosho seems

to concentrate on the nitty-gritty: an upright steering servo with a

good linkage lineup causes linear steering action and is exposed to

less transverse force at maximum throw than a laydown steering

servo.

The radio box can be numbered among the more spacious ones in the

buggy/truggy class and offers seperate compartments for receiver and

battery (up to five AA cells can be fitted in easily).

The fuel tank is located to the left of the center diff and equipped

with an overfill fuel channel and an internal stone fuel filter (to

avoid air bubbles in the fuel line and ensure stable engine

operation even if the Inferno ST takes a longer spread-eagled rest

on its roof after a rollover). Power is delivered by a 4.6ccm GXR-28

pull start engine connected to a two-piece aluminum tuned pipe.

|

|

|

Appraisal:

driveline and suspension |

|

|

|

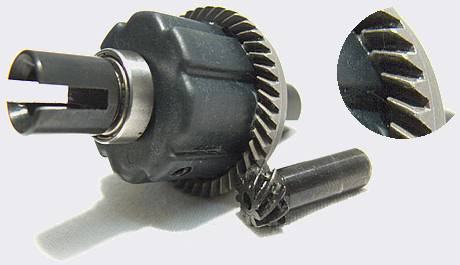

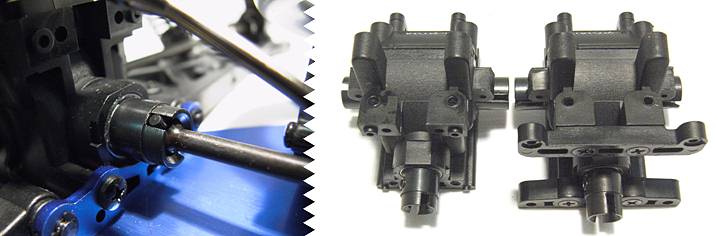

Once again we

start our review where there is not much left to disassemble: The

differential gears. As usual, the Inferno ST US Sports is using

three of them, the centre differential balancing differences in

rotational speed between front and rear suspension and thusly

allowing to adjust the braking balance.

The differentials of the Kyosho truggy are built like one would

expect them to be for an 1/8th scale off-roader: rugged o-ring

sealed plastic body, steel crown gear and solid outdrives. But two

juicy details are hidden inside the diffs of the ST US. |

|

To withstand the greater forces that

would come up in a truggy, Kyosho decided to use spiral gears for the

differential. In comparison to straight cut bevel gears this type has a bigger

contact surface and a better meshing - in short the spiral

gears run smoother and can take greater forces.

Although the crown gear is cast

steel the (sharpened) macro view shows an amazingly high surface

quality. The bevel gear is made of machined steel and hardened

afterwards. |

|

|

A type of precision rather uncommon

for this price range becomes apparent here: With 7.98 millimetres

the bevel gear shaft clears the bearing for only two hundredths of a millimetre - a sensible measure given the precision gears.

Normally the clearance ratio of the bevel gear would be four

hundredths of one millimetre. |

|

|

Now, if the intricate gears should

enhance the stability of the differential then the things that lurk

inside it can (not even) be understood as a paradox:

The differential is ready for a four spider setup but with the

notorious SPORTS-series traditionally only two spiders will manage

to cheat their way into the diff case.

Bevel gears (IF-102) and satellite shafts (BS-107) are needed

for upgrading two differentials. To rebuild the center diff as well,

a second IF-102 bevel gear set becomes due. Four bevel gears will

not only enhance load transmission but also stabilize the outdrives.

The upgrade will cost you €20 (Kyosho Germany retail price) |

Realistically

speaking the stripped down diffs will bear up for quite some time.

Comparable amounts of torque are transferred upon the crown gear and

(with two spiders) to every bevel gear due to the different

distances of the gears from the rotational axis of the diff.

Nonetheless four spiders will stabilize the outdrives in two planes

(up/down - left/right) under load condition while two bevel gears

can only support them in one plane. As a consequence greater stress

is put upon the friction-type bearings of the outdrives. If this

caused bearing play the meshing between sun- and spider gears would

be impaired - this increases diff wear and the bevel gears will be

ruined due to excess bearing clearance.

Anyway, the high grade of the assembly

has to be appreciated: the diffs are well shimmed, run

smoothly and are filled with silicone oils of different viscosity. (front:medium,

center:hard, rear:soft) |

|

|

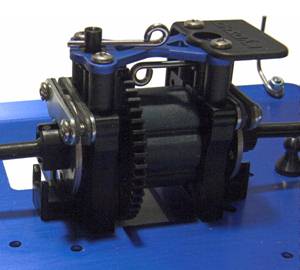

The gear boxes are of the 'one-chunk wonder' type; meaning that they will not only encase the

diff and bevel gear but also hold the caster blocks and the shock

towers. Therfore the gearboxes have to be built sturdier than the

elastically supported boxes of the Robitronic Mantis Truggy for

example. (click for a

picture)

Both gearbox halves feature a sealing lip and fit together without

any play. The differentials are factory shimmed - and dead right

they are. After putting together both gearbox halves I can say that

in my whole hobby career I have never experienced a bevel gear that

would run so smoothly and nearly noiseless. No sticking, no tight

spots, no rattle, no tedious fiddling around with shims... the gears

mesh perfectly without even having been run in - it's just wonderful!

For this reason these gears can be counted to the high-grade ones on

the current buggy/truggy market. Enough grease has been supplied (which

was just removed in order to take some photos) so there are no

complaints about the assembly of this critical component - when

counting the economised bevel gears to the equipment section.

With "e-clipped" hinge pins the

suspension is connected to the gearboxes. It can only be

distinguished from a buggy suspension when compared in length.

Dirt-shielded c-hubs remain in the realms of the ST-R. |

|

The wheel adaptors are also different

from the ST-R and the buggy standard: instead of an aluminum hex

with M10 fine thread the ST feels more at home with the 1/10th

scale standard: The wheel is secured to the axle by an M6 locknut. The

14 millimetre metal hex is grown to the standard 17mm size with the

help of a plastic adaptor. With the 14 millimetre hexes some monster

wheels can be fit on too - provided that they got an inner rim diameter of

at least 77 millimetres and 36mm maximum offset.

The whole concept may look a bit funny to 1/8th buggy drivers and is

probably the result of budgetary cuttings when compared to the ST-R.

But thanks to the chequered locknuts the system provides a reliable

wheel mounting.

|

The Inferno

ST

uses e-clips on nearly all suspension parts.

The more elegant screw-pins are only sporadically

used at the shocks and the upper suspension arms. |

|

|

Luckily the plastic parts

are generously sized so that there are one or two spots

left where an M3x5mm grub screw can be put in to secure

the hinge pins, witch need some notching with the dremel

where they meet with the grub screw. The forward

pointing e-clip should remain on the hinge pin. |

|

|

|

No

set screws are needed at the front suspension arms

because the front bumper keeps the hinge pins in

position! Therefore the e-clips on the back side can

also be kept as spares. |

|

|

|

Kyosho goes plastic with the shock

absorbers.

On both front- and rear suspension they are 116 millimetres long and

can only be distinguished by the minor spring preload at the front. |

|

The preload (and therefore the ground

clearance) can be easily set by a knurled nut so there is no need

for plastic clips.

From the outside the shocks give a good impression. Even though they

are not as perfectly filled as the Robitronic Protos shocks they

feature an excellent smoothness not often found with RTR-models. The shock absorber

on the top right picture has been quickly compressed for a couple of

times. However the photo shows absolutely no leaking of oil.

Perfectly recognizable though is the absence of a securing clip. That

means the sealing o-rings are installed into the

shock body from the inside - not so great. The shocks generally don't

appear

maintenance-friendly at all because the damper cap is likely to cant

while screwing down and can only be tightened with the guiding help

of the knurled nut. (in case it remained on the shock body in the

disassembly process) |

|

The first rebuild will not

be too far away because there is no way to fix any shock

boots to the smooth body.

Shock absorbers of equal quality like from the

Robitronic Protos or the Sports buggy series (MP 7.5

Sports) are favourable here.

If the rigidity of the

plastic shock body is adequate -especially with the

almost lay-down front suspension- remains to be

seen.The

shock towers are taken directly from the Inferno MP 7.5

buggy. Unlike the ST-R the ST has a more of a

laydown

front shock geometry due to a smaller shock tower.

A thickness of 2.9 millimetres may not be too

overwhelming but the low-mounted body posts and the

truggy bodyshell should present an appropriate

protection for the shock towers so no bent parts have to

be feared of. |

The shock mount turned

out nice: At the suspension arm screw-pins

are used - unlike the more complicated type on the ST-R

which employs grub screw-secured rods.

At the shock

tower the steel ball is held in place by an

Allen screw and a locknut on the rear side. The

chequered locknut is pressed against the shock tower

when tightened and thusly prevents twisting. This type

of mounting reminds a bit of the Lunsford Racing quick

change system.

Equipped only with an Allen wrench and a Phillips

screwdriver shock positions can be changed quickly. In

order to take advantage of this feature the ST offers

five mounting holes on each suspension arm and even more

on the shock towers. (four at the front, six at the rear) |

|

|

|

|

|

| Power

transfer is done without universal shafts

but the suspension is built so

that the dogbones will stay put - without the

need of lugs - over the whole suspension

travel. Furthermore there is enough play so

that the dogbones will not bind up or fall

out, even when facing flex which is

generally inherent with suspension arms of

this length - nice job! |

|

|

|

|

Chassis details |

|

|

|

Because Kyosho's

Inferno ST follows the classic buggy concept there are no real

surprises in between the front and the rear end.

But it should not remain unmentioned that assembly-

and material-quality of the (plastic-) parts is as excellent as

the assembly of the RTR-model.

|

|

Eight bolts

(and the two servo screws) have to be loosened in

order to take out the R/C unit of the Inferno

ST.

As mentioned in the beginning, Kyosho laudably

employs servos mounted upright. Hence the radio

plate is exclusively held by four plastic posts.

(and the fourfoldly attached radio box)

In comparison to their MP6 predecessors these

posts have become way sturdier so that upgrading

them with aluminum posts (IFW-113) does not seem

necessary even with stronger servos.

The servos that come with the kit are both

labeled Perfex KS-1401. The plastic gear servo leaves a

bit of a strange impression but more on that in

the second part!

The radio box is of

the "bigger is better" kind - which is always good thing

to be!

The battery tray will accept nearly any four- or

five cell battery pack. (Here: 5x Sanyo AA 2500 mAh

NiMH - in GP cars only soldered packs should be used!) |

The compartment next

to it is a wee bit smaller. But also here it is

enough for a standard receiver, (42x35x20 mm)

thoroughly wrapped into sponge rubber.

An on/off switch is hidden at the rear side of the

radio box, protected from dust and grime by a rubber

sleeve.

To give the radio plate a more "racy" look it is

equipped with a transponder mount. The position is

rather badly chosen (due to the missing sideguards)

because the transponder dangles more or less freely

in the open. |

|

|

|

Between the front and rear suspension,

erverything is aligned

purposefully around the centre differential

block.

Latter is equipped with (seperately adjustable)

disc brakes.

In order to prevent canting of the vented steel brake discs a

pair of brake guides is

mounted to the chassis plate. Each guiding thingy

can take up to two discs.

A four-disc brake will not only need further

brake calipers but also longer pad mounting screws.

Talking about the brake calipers: These are

self-releasing, meaning that they do not need

any spring to push them apart after braking. The

calipers have enough play so that they can be

realigned solely by the brake disc - which works

smoothly with the Inferno ST.

To increase the durability of the brake pads

they should be glued firmly onto their steel

shoes! |

|

The front brake is

equipped with a fuel splash guard. This should

prevent soaking the brake disc in the course of

over-enthusiastic refueling maneuvres and

therefore reducing brake power caused by the

residual oil. In order not to get the chassis

all manky with dirt the tank features an

overfill fuel channel that will accept excess

fuel and guide it through the chassis to the

ground.

As we're talking about fuel: As shown in the

picture below the engine is mounted directly onto

the chassis in good old Sports-fashion, although

(compared to the GS-21R) the crankcase already

has 'proper' mounting lugs. Luckily the chassis

accepts motor mounts but the fact that they are

nowhere to be found in this kit (also facing

equally priced truggy-competitors) is a clear 'no-go'

equipment-wise.

If you wanted to provide your GXR-28 with a more

stable base or race other engines as well you

would have to pay about € 20 (Kyosho-Germany

retail price)

for the engine mounts. (IF-107 and

IF-108 are needed) |

|

|

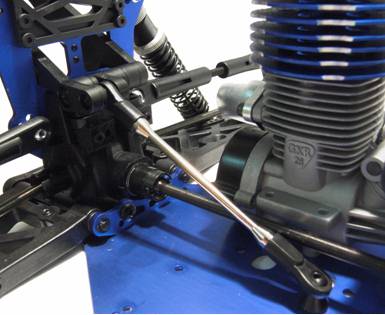

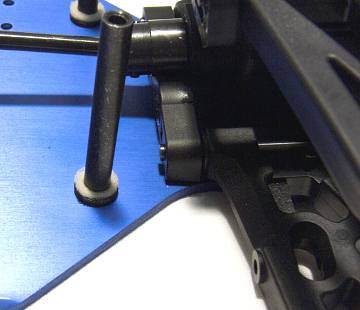

To support the long truggy chassis both

gearboxes are equipped with torque rods, the

Kyosho-like design consisting of two ball ends

and a threaded rod.

There are numerous 'hop-up rods' by aftermarket

suppliers that are milled out of an aluminum

block and promise even more rigidity but I have

had positive experiences with the ball end

thingy that can give a little in an emergency

situation. And there always remains the question

of personal taste - whether you like a 'harder'

or a more flexible chassis.

A harder chassis provides a more precise

handling

but setup mistakes are more likely to cause the

truggy behave badly. |

|

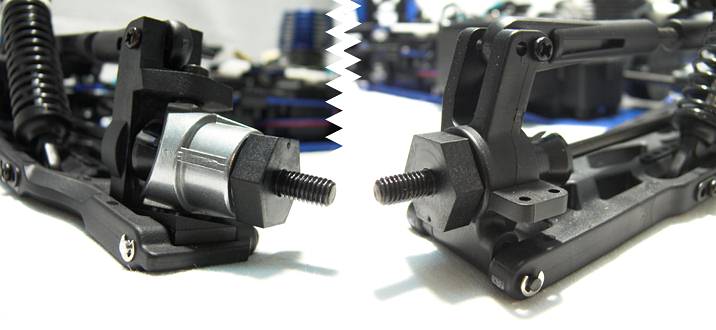

The chassis' flex could cause problems for

totally different reasons. I praised the

suspension because it would -not nearly- let the

dogbones bind up or fall out over the full

suspension travel but the rear part of the chassis might

not come out that praiseworthy.

The photo down to the left shows the dogbone to

the rear gearbox. There is not much play due to

corresponding lugs inside the centre diff

outdrives that could give way (eg. after a

harder langing) without risking to bend the

dogbone.

At the same time there is not much left that

could keep the dogbone from falling out if the

chassis flexed too much. There seems to be no

reason to use the short joint cup especially

when a longer version actually exists - looking

at the front gearbox in the picture down on the

right.

For fairness reasons it has to be admitted that

the rear part of the chassis is really firmly

built which makes it virtually impossible to 'tease'

the dogbone out with your bare hands.

Anyway, as an off roader you know the forces

that are at work when you're proverbially off

the beaten track - so only pracitcal

experience will show whether the

short joint cup is enough or not.

|

|

|

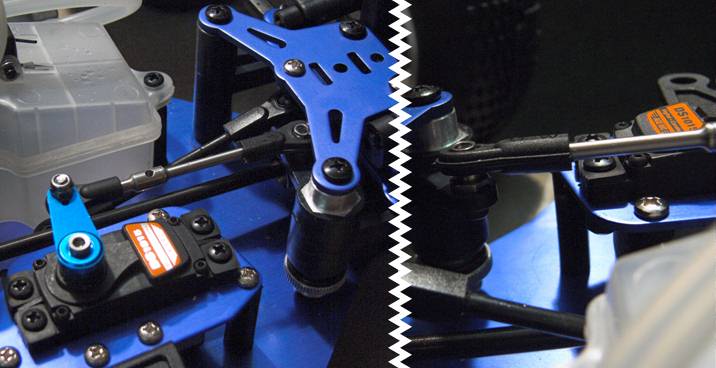

Last but not least

comes the steering. Tried and tested

parts of the eigth-scale buggy-world are put to use. Hollow

6-millimetre steering posts reinforce the front

gearbox - it's just the kind of steering setup

we like!

The beefy steering arms seem to be made of a

harder type of material than the other plastic

parts. The adjustable servo saver features a

heavy spring with a wire gauge of 1.5

millimetres. Out of the box it is set as soft as

possible - supposedly to go easy on the servo

gears.

All in all it's a solid piece of work that will

also get along with stronger servos. (plus 10kg*cm

would be recommendable for the steering) |

|

Something

about this steering should look a bit odd

to the

observant reader who has already had contact any 1/8th

offroad car

... the last

hint is provided by the picture on the right -

before the 'puzzle' is solved.

...

...

|

|

|

"In dubio pro reo" - and Jamara proved it

with the 'Track-Sau' that it is indeed possible

that a cropped 2 millimetre steering link can

work with a plus 4kg car.

The only thing is: Jamaras' link was two

centimetres short, absolutely parallel to the

push/pull direction and connected to the

steering arm by a five millimetre double-sided

adaptor. (see

picture)

Kyosho's version is about

three times as long, not parallel to the

push/pull direction (because the linkage

declines a bit towards the steering) and is

connected to the steering arm by a three

millimetre single adaptor. Lacking a counter bearing this induces more play

than all the other connections of the steering

altogether.

The good news:

Even with a supply voltage of 6 volts the 'bent

wire' remains pretty unimpressed by the (servo

saver-alleviated) steering power of the servo.

The bad news: It needs a much stronger servo and

a way harder servo saver to tap the full

potential of the Inferno ST. |

|

|

The Tragedy behind it? For just € 10 you could

have an 'offroad-proof' luxury linkage using a

stainless steel turnbuckle and six millimetre ball ends

free from float!

It remains unclear, why Kyosho decided to

give up the perfectly able linkage of the MP-6

Sports Buggy and use the linkage shown above. |

|

|

|

Steering

- reloaded! |

|

|

|

OK, let's assume that you

overlooked the last couple

of pictures ...

Then here's how to assemble the steering linkage of Kyosho's

RTR-truggy! ;-)

First some thoughts:

-

In principle a linkage could be

everything stable enough and with the possibility to mount it onto

the servo saver with an M3 screw. Depending on the construction

the servo saver might have to face "outwards" because the linkage

could touch the reinforcement plate which connects the steering

posts to the gearbox. I'd like to avoid the outward

steering link, the inward-type looks classier and is better

protected.

-

For Kyosho is using an upright

steering servo against current (promotional) opinions the merits

of this kind of setup shold be taken advantage of. This implies a

parallel linkage lineup from steering arm to servo saver to avoid

transverse force.

It can be difficult to

get the linkage "high enough" on the servo side.

Especially

when the servos were mounted without vibration-reducing rubber

pads.

For cases like that Academy or HPI offer threaded 5.8

millimetre ball studs with a low installation height. A ball

stud like that is attached to the servo arm with a locknut.

Another ball stud is used at the servo saver. It should be one

of the kind that have to be secured with a screw from below -

don't forget your threadlock!

A turnbuckle is used to connect both ball ends - it should be

between 50 and 55 millimetres long. |

|

|

|

|

|

The pictures above show that I've

worked ahead a little bit and got rid of the original servo in

favour of Thunder

Tigers' DS1015. The torque readings in part two will show why.

Another hint: The Inferno ST US's steering

uses only friction bearings but still it's not a bad idea to prevent dust from getting into them. Before the

steering arms are set onto the posts a piece of foam rummer

should be put on. This helps reducing the steering float and

furthermore no (astonishingly fast) grinding dust can settle.

Foam rubber is also vital should you choose to upgrade a

ball-raced steering: The small ball bearings are pretty

damageable!

|

|

|

|

Checkpoint! |

|

|

|

Interim

results - truly not easy!

Kyosho's newest RTR-Truggy is a sophisticated concept. But

in practice it seems rather rough - perhaps an allusion to

the preferential field of application of the Inferno ST?

First example: On the one

hand the US-Sports excels with luxury gears - but then the

budgetary red pencil gets in the way of a consequent

continuance that would allow for four bevel gears. (at

least for the front and rear differential)

We'll have some other examples coming along until the final verdict.

To push this

in perspective: It's laudable when a manufacturer like

Kyosho takes the meaning of "RTR" serious and presents an

excellently assembled car - quality control will have its

share at the € 559 retal.

And apart form the example listed above - plus the missing

engine mounts and the absurd steering linkage - at least

the rest of the provided equipment is about average.

A well equipped fuel tank (stone filter, overfill

protection

and good fittings), steel gears, well glued high-grade

tires with foams and the big separated radio box millitate

in favour of Kyoshos' truggy.

Only: They can not really drown the bitter smack that is

left by the shortcomings that are way below class

standard.

|

|

Text and photography by

Aaron Banovics,

translation by Markus Simon

This article has been published on

www.offroad-cult.org

on 12.12.2006.

|

|